Table of Contents

- Surface Protection Function

- Antistatic Function

- Thermal Stability

- Ease of Removal

- Environmental Safety

- Principle Analysis

- Weather and Moisture Resistance

- Conclusion

- References

Meta Description

PE static films protect PC boards from electrostatic discharge, moisture, and scratches, offering easy removal, reusability, and eco-friendly, non-toxic performance.

Body

A PE static film is a protective film that acts as a barrier, safeguarding sensitive surfaces against damage. These films are used widely to protect PC boards because of their ability to prevent electrostatic discharge that can damage sensitive components.

It helps prevent damage due to environmental agents like dust and moisture and reduces the risk of scratches during the production, storage, and transportation of PC boards. The PE electrostatic films are preferred for their ease of application and removal without residue. Moreover, their eco-friendly nature and ability to be reused multiple times make them a much sought-after option for eco-conscious customers.

Let’s have a look at some of the ways in which they protect the PC boards, making them an ideal choice.

Surface Protection Function

PC boards are highly sensitive components and minor contamination can result in a negative impact on the performance of various components. PE films help protect the surface in the following ways:

- These films prevent dust particles accumulation on the surface, thus preventing damage to the surface as well as to the components inside.

- It also shields the PC boards against moisture and humidity thus keeping them dry and clean even in humid environments.

- During manufacturing and transportation, the PE static films provide considerable protection against abrasion and scratches due to rough handling, maintaining their pristine condition.

Antistatic Function

One of the reasons why PE static films are particularly considered for protecting PC boards is their ability to resist an electrostatic discharge. An electrostatic discharge can be damaging to the microelectronic components in a PC board and can considerably impact their performance. A static film provides a cost-effective solution to this problem and prevents the intricate components by reducing the risk of electrostatic discharge.

Thermal Stability

While the standard, unaltered versions of PE static films are not resistant to high temperatures, these are mostly combined with temperature-resistant additives. One such example is that of cross-linked PE i.e. PEX. It has additives that enhance its thermal stability and it can hence bear moderately high-temperature processing stages. It is also used for temporary bonding and lamination before the bonding stage.

Ease of Removal

- PE static film is by nature a low tack adhesive film. Its low adhesion makes it ideal where easy removal is needed. The low adhesive strength makes it possible to ensure clean removal without leaving residue.

- It does not stick unevenly and hence does not tear off even when removed after prolonged application.

- PE films can be mostly reused because of their strength and because they maintain their integrity even after repeated use. This helps reduce costs and allows multiple applications. It is an ideal characteristic for the PC boards when they go through inspection and the protective films need to be removed and re-applied, or swapped.

Environmental Safety

· Compliance with Environmental Protection Standards

PE static film is among the safer options for surface protection when it comes to choosing non-toxic materials. It is devoid of harmful elements like BOA or heavy metals and hence meets environmental safety regulations like RoHS.

· No VOCs

The manufacturing and processing of PE films does not emit Volatile Organic Compounds (VOCs) which are among the biggest contributors to environmental pollution in manufacturing industries.

· Recyclability

PE static films are completely recyclable making them a preferred option or environmentally conscious customers. It helps reduce the burden on resources.

· Energy Conservation

The production and processing of PE static films generally use less energy as compared to other polymers. It is made using energy-efficient production processes.

Principle Analysis

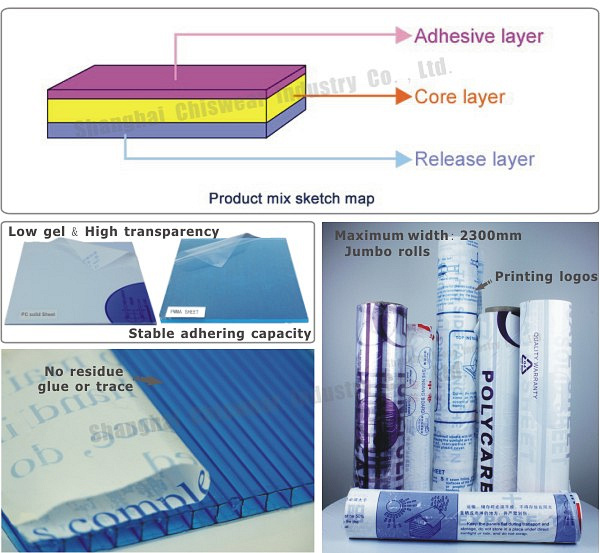

The ability of the PE static film to cling to the PC Board’s surface is a result of two phenomena, i.e. multi-layer co-extrusion and static adsorption.

The Principle of Static Adsorption

The ability of PE film to produce a static charge helps it to adhere to the surface of the PC boards and hence no adhesive is needed as a natural cling is produced due to static charge.

The reason why this natural static cling is preferred in the case of PC boards is because it doesn’t use the chemicals that constitute an adhesive and hence the sensitive components of the PC boards will not undergo any malfunction due to these chemicals. Moreover, these adhesive-free films offer easy application and clean removal.

Multilayer Co-extrusion

This technology allows combining various layers of PE static films into a single layer for optimized performance as each layer performs a particular function. For instance:

- Top layer provides a scratch-resistant barrier.

- The middle layer is meant to give the required strength.

- The innermost layer ensures utmost static adsorption for secure bonding.

Weather and Moisture Resistance

- The PC Boards are meant to house sensitive components that can be damaged due to oxidation under humid and moist conditions. The hydrophobic nature of PE static films makes them an excellent solution to this problem. They naturally repel moisture, keeping the PC boards dry and their components safe.

- This property also ensures that the mold and fungi do not develop on the surface of PC boards because the PE static films do not let the vapors and moisture accumulate.

- Moreover, most of the PE static films today are manufactured by adding UV-resistant additives. Hence the films do not turn yellowish or degrade due to prolonged exposure to sunlight.

Conclusion

PE static films offer a comprehensive and effective solution for protecting PC boards throughout manufacturing, storage, and transportation. Their anti-static properties guard against electrostatic discharge, ensuring the safety of microelectronic components, while moisture resistance prevents oxidation and contamination. The film’s ease of application and residue-free removal make it ideal for workflows requiring frequent reuse, reducing both operational costs and environmental impact. Additionally, multi-layer co-extrusion technology optimizes performance, providing strength, surface protection, and secure adhesion without adhesives. With environmental safety through recyclability, non-toxic composition, and energy-efficient production, PE static films are an eco-conscious, practical choice for protecting sensitive PC boards.