Table of Contents

- Overview of PE Profiles Protective Film

- Overview of PE Static Film

- Comparison of Uses

- Analysis of Usage Characteristics

- Conclusion

- References

Meta Description

PE Profiles and Static Films provide durable, versatile protection for surfaces across industries. Choose profiles film for strong, lasting adhesion or static film for easy, residue-free removal.

Main Body

Polyethylene (PE) protective films play an essential role in protecting the surface of products from scratches and other damage in virtually every industry. These films act as barriers from scratches, dust, contaminants, and light impact so that the products look new and scratchless during manufacturing, storage, transportation, and end-user handling. By protecting the surface against these damaging agents, PE protective films reduce reject rates, lower waste, and help eliminate excessive rework. Moreover, these films, through their aesthetic appeal, improve the product’s appearance, increasing customer satisfaction.

PE protective films have a wide scope of application. They protect monitors, glossy panels, and other electronic products, protecting their delicate surfaces against scratches and smudges during manufacturing and shipping. In the automobile industry, these films are used to cover exterior parts of cars, interior components, and glass on the assembly line and in transit. In construction, PE films are used for protecting surfaces such as glass, aluminum, and tiles right from the manufacturing to the installation stage. They are also used on metal sheets, plastic panels, and furniture. In short, these PE protection films have a huge role to play in protecting the integrity of all sorts of products and adding to their aesthetic appeal.

Overview of PE Profiles Protective Film

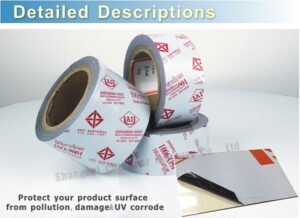

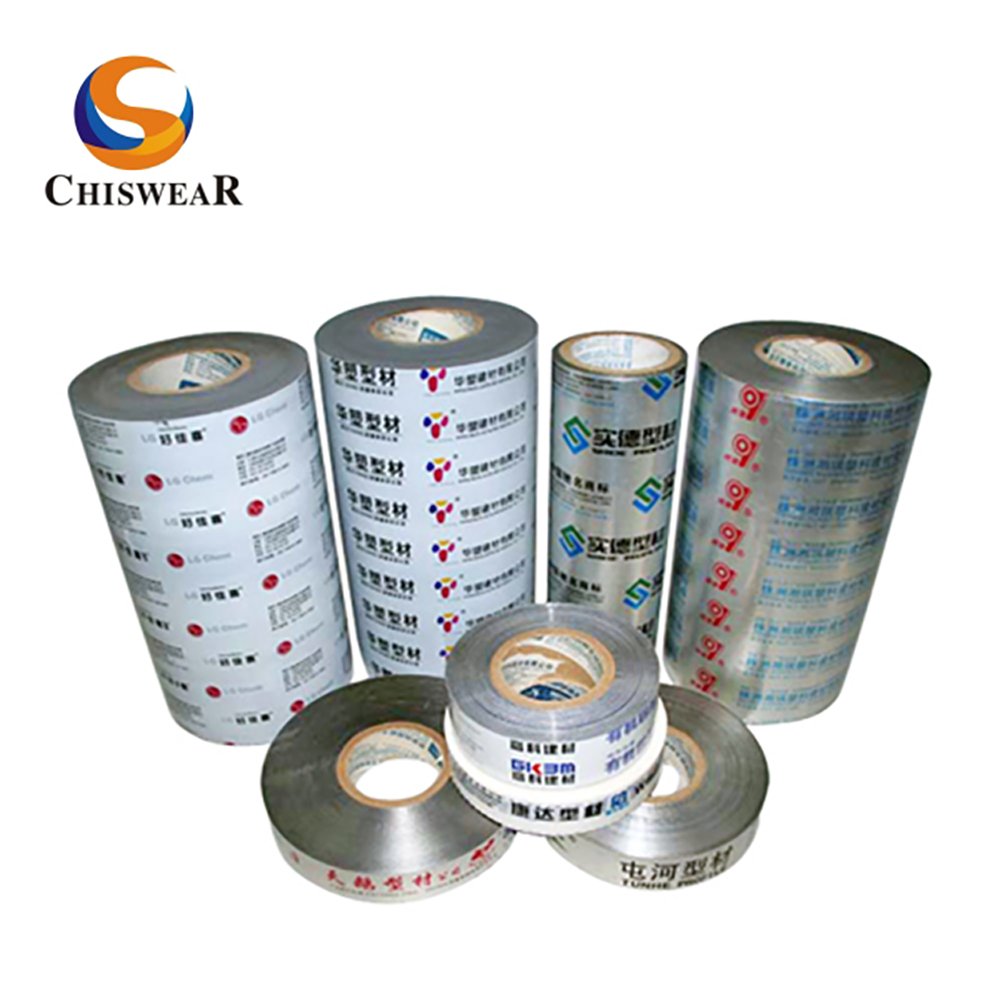

PE profile protective films are particularly suitable to be used for protecting profile surfaces including aluminum, metals, and plastic. Their flexibility and durability ensure that they can be used for all shapes. Let us have a look at why these films are ideal for profile protection.

Characteristics

- Their high-quality polyethylene material is durable and yet highly flexible, making these protective films suitable for intricate surfaces.

- These are ideal for sensitive, delicate surfaces because PE films made using an appropriate quantity of adhesive are usually easy to apply and easy to remove without leaving residue.

- The high tensile strength of PE allows these films to endure rough handling during transportation and daily use.

UV Resistance and Weather Resistance

- PE films are made keeping in view the exposure to moisture and extreme temperatures.

- When these films are intended to be used outdoors with prolonged exposure to sunlight, e.g. for outdoor storage, resistant additives are added to make them capable of withstanding prolonged UV exposure.

- The anti-UV and weather-resistant films PE films do not allow the surfaces to be damaged, degraded, or discolored.

Strong Adhesion

- Strong adhesive strength makes PE films firmly in place which makes them suitable for surfaces with complex geometries.

- Although they stick firmly, OE profile films do not leave a residue upon removal.

- High adhesive strength also makes them suitable for protection during assembly and transportation where there can be high impact and rough handling.

Overview of PE Static Film

The PE static films are among the most unique protective films as they don’t use any adhesive. The PE static films use a static charge to stick securely to a surface. These can be used to protect glass, fragile screens, plastics, polished surfaces, and more.

Working Principal

The static films make use of a different in static charge between themselves and the surface to be protected and hence cling to the surface due to the attraction provided by this difference.

Since these films cling to a surface securely without using any adhesive at all, they don’t leave any residue and are hence suitable for short term or temporary protection. For example these can be used during storage, in assembly lines, during transportation, etc. once the product reaches its destination, the static film can be removed with absolutely no trace on the surface.

Application Scenarios

PE static film is utilized in a wide range of situations where light duty applications are preferred and mess-free removal is needed.

- It protects glass, polished metal or acrylic surfaces against scratches during brief periods of handling or transportation.

- It is also used to protect screens, such as displays of electronics or panels, mobile screens, wearables. Etc.

- Also, it finds application in cleanrooms where adhesive films would attract a lot of contaminants.

- PE static film has its most appropriate application in those cases where the film will be displaced and then replaced frequently as the properties of the static film allow for multiple applications and removals without negatively impactive its protective traits.

Comparison of Uses

PE profile protection films are usually suitable in those scenarios where the requirement is prolonged protection and strong adhesion. Moreover, these films will be preferred over static films when the surface to be protected in complex and has different intricate geometries.

For example, in construction industry, these films provide strong adhesion as needed during storage at construction sites, rough handling during manufacturing, assembly, and transportation, and intricate structure of PVS profiles and aluminium profiles.

Similarly, in automotive industry, PE profile protection films with adhesives are preferred at various stages to protect metallic and plastic parts that are subject to rough environments and careless handling. Same is the case with furniture where the sharp edges curved shapes need to be protected by a film that adheres firmly.

The PE static films on the other hand are preferred where short-term protection is needed and aesthetics are of prime importance, hence the film must not leave any residue upon removal. This is why these films are ideal for protection of electronic devices, glass panels, and polished surfaces. Moreover, these films help in cleanroom settings where temporary protection from dust and contaminants is needed.

Analysis of Usage Characteristics

The difference in the traits of PE profile protection films and PE static films make them suitable for distinct scenarios. for example, the durability of PE profile protection films is its core trait making it useful for applications like protecting construction materials and automotive parts.

The statis films on the other hand boast about clean removability, replaceability, and reusability. These core traits makes these films a preferred choice for protecting delicate surfaces like screens of smartphones, tabs, and wearables. There reusability means these films are ideal where the products need to be inspected several times.

Conclusion

In summary, PE Profiles Protective Film and PE Static Film each offer tailored surface protection across industries. PE profiles protective film provides durable, strong adhesion ideal for long-term protection of construction materials, automotive parts, and complex shapes, with added resistance to weather and UV exposure.

PE static film, using static cling for easy, residue-free removal, is best suited for short-term applications, particularly on delicate surfaces like electronic screens and glass panels. Its reusability and clean removability make it ideal for settings needing frequent inspection, such as electronics manufacturing and cleanrooms. Together, these films provide versatile, effective options to meet diverse protection needs.

References

- https://www.sciencedirect.com/topics/agricultural-and-biological-sciences/polyethylene-film#:~:text=PE%20and%20other%20plastics%20are,density%20range%20similar%20to%20LDPE.

- https://chidecor.com/product-category/protective-film

- https://en.wikipedia.org/wiki/Ultraviolet

- https://chidecor.com/product/pe-aluminum-film-for-pvc-profile/