Table of Contents

- Introduction

- 1. Application of Aluminum Profiles in Photovoltaic Bracket

- 2. Application of Stainless Steel Profiles in Medical Instruments

- 3. Application of PVC Profiles in Building Windows and Doors

- 4. Application of Aluminum Alloy Profiles in Rail Transport

- 5. Application of Plastic Profiles in Home Appliances

- Conclusion

- References

Meta Description

Discover the benefits of profile protection films for aluminum, steel, PVC, and plastic profiles. Safeguard surfaces against scratches, UV, contamination, and damage.

Introduction

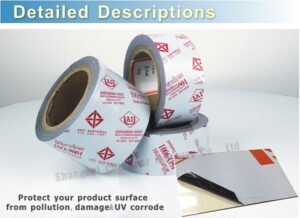

Profile protection films are specially made to protect the surfaces of profiles made with varying materials. These films are usually made of polypropylene (PP), polyethylene (PE), or PVC material and are used to protect the profile surfaces against moisture, abrasion, scratches, UV exposure, chemical abrasion, and dirt. They can be used to protect the profiles of wood, plastic, steel, aluminum, and others.

The profile protection films come in varying thickness and formulation according to the intended use and they safeguard the integrity and appearance of profiles during manufacturing, storage, transportation, installation, and even after that to keep the profiles looking new for long.

These films can be transparent and clear or printed with instructions company logo, etc. Moreover, these are made to ensure easy application and removal without leaving residue or damaging the surface. Let us explore a bit more in detail about the profile protection films for various types of profiles and how they help provide much-needed protection.

1. Application of Aluminum Profiles in Photovoltaic Bracket

Background

Photovoltaic brackets or solar brackets provide support for the solar panels and help ensure their perfect mounting and optimal orientation. These are being increasingly made using aluminum profiles. The recent increase in the use of aluminum profiles for photovoltaic brackets is because aluminum is comparatively very lightweight as compared to other materials like steel and hence it provides ease of transportation. Moreover, due to its high flexibility, it can be made into different shapes to support different structural needs.

However, aluminum profiles can easily get damaged. They can get scratched and get damaged during transportation. Moreover, since these are meant to be used outdoors, these aluminum profile brackets have to endure UV exposure and extreme weather conditions throughout their life and hence they need protection.

Solution

Aluminum profiles need to be protected right from manufacturing to transportation, storage, and installation. To safeguard them against damage, dust, and scratches, aluminum profile protection films are absolutely unavoidable. These films are great at enduring impact and providing a barrier against scratches. Moreover, specially formulated UV-resistant films provide the much needed protection against UV exposure, helping safeguard its integrity.

Effect

These aluminum profile protection films can significantly reduce the risk of damage during manufacturing, storage, and transportation, hence reducing the cost of rework. Moreover, they extend the lifespan of photovoltaic brackets by protecting against continuous exposure to UV rays.

2. Application of Stainless Steel Profiles in Medical Instruments

Background

Medical instruments made with high grade steel are required to met quite a few stringent standards when it comes to hygiene, surface integrity, resistance against corrosion, and contamination. During production, transportation, and use, these can undergo contamination due to pollutants and the abrasions can cause hygiene challenges as well.

Solution

Specially designed high-quality stainless steel profile protection films are used to protect stainless steel against contamination. These films have a composition that allows them to withstand sterilization procedures and heat while protecting the surfaces against germs. Moreover, these films do not leave any residue upon removal.

Effect

Stainless steel protection films help simplify the cleaning process and meet stringent health, safety, and hygiene standards by keeping the steel protected against contaminants. By resisting abrasion and scratches, the risk of contaminants accumulating on the surface is greatly reduced.

3. Application of PVC Profiles in Building Windows and Doors

Background

PVC profiles are extensively used in the building industry. These are mostly used in windows and doors. During manufacturing and transport, PVC profiles can easily get damaged and are especially prone to scratches. Moreover, when used outdoors for extended periods of time, exposure to UV rays and harsh weather conditions can also damage them.

Solution

PVC profile protection films are very helpful in protecting PVC profile surfaces against scratches and damage due to pollutants and harsh conditions. Their high transparency allows complete visibility and hence the aesthetics are not undermined. Moreover, string adhesives protect the premature peeling of the films while they are still easy to remove without leaving residue.

Effect

PVS profile protective films help maintain the aesthetic appeal and integrity of the surfaces. It reduces the risk of scratches during transportation, handling, and installation. Transparent films also ensure PVC profiles can be inspected without having to remove the films.

4. Application of Aluminum Alloy Profiles in Rail Transport

Background

Alluminum alloy profiles are one of the most commonly used material in trains, trams, and subways due to the high strength and low weight of alluminum alloys. However, when used for the interior and structural parts of the trains, these alloy profiles face challenges. During manufacturing, handling and transport, they are prone to scratches and dirt accumulation. Moreover, due to passenger contact, these parts need to maintain their spik and span condition.

Solution

High quality alluminum alloy profile films are made to protect the interior and structural parts of vehicles. They provide a barrier against scratches and dirt.

Effect:

By protecting the surface these films improve maintain aesthetics and enhance customers’ overall experience and comfort.

5. Application of Plastic Profiles in Home Appliances

One of the most commonly used profiles in home appliances are the plastic profiles. This is because they are comparatively cheaper, durable, and last longer. However, despite all their strengths, these plastic profiles face quite a few challenges. For example, they are prone to scratches, and deshaping due to impact, grease and dirt accumulation, decoloration, and wear.

Solution

The solution to all the above-mentioned challenges is the use of specifically formulated plastic profile protective films. These films protect against scratches, impact, and contamination during production, transportation, and handling. Moreover, they can provide comprehensive coverage as these films can adhere even to the complicated shapes and edges.

Effect

The barriers provided by these films ensure an intact, polished surface and attractive appearance for plastic profiles. They help retain the product’s quality and this translates into customer satisfaction.

Conclusion

In conclusion, profile protection films play a vital role in safeguarding the integrity, aesthetics, and longevity of profiles across various industries. From aluminum photovoltaic brackets to stainless steel medical instruments, PVC building components, aluminum alloy rail transport parts, and plastic home appliance profiles, these films provide tailored protection against scratches, contamination, UV exposure, and other challenges. By reducing damage, enhancing durability, and maintaining visual appeal, profile protection films offer practical and cost-effective solutions that ensure product quality and customer satisfaction