Table of Contents

- Introduction

- Overview of the UV Curing Technology

- Market Feedback and Demand Growth

- Environmental Trends and Sustainable Development

- Marketing Strategy Recommendations

- Conclusion

- References

Meta Description

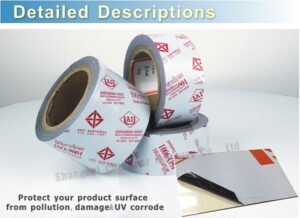

Have a detailed look into how UV curing helps enhance the quality of protective films while lowering poser consumption and ensuring quicker cycles and reduced costs.

Introduction

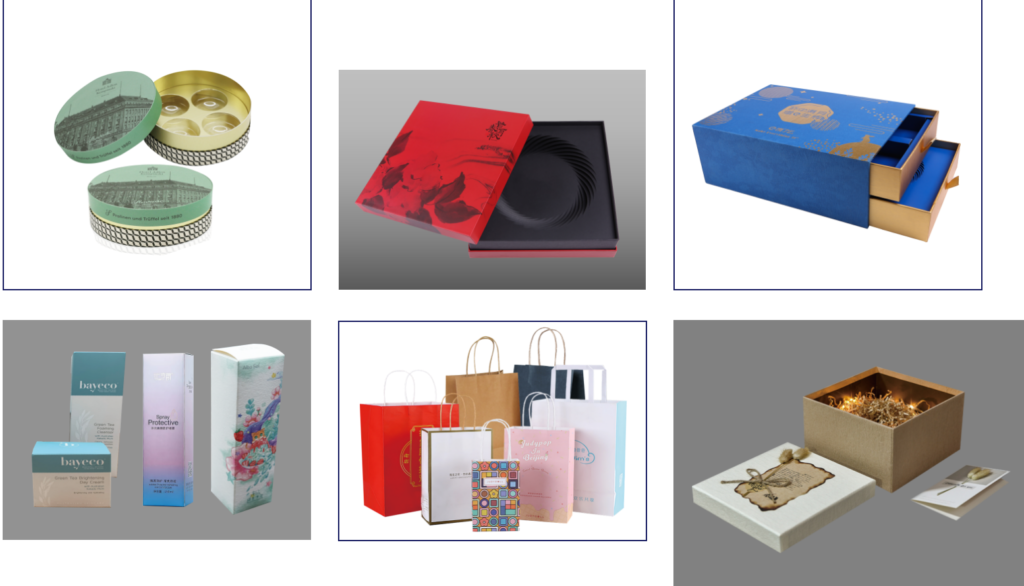

Technological developments have taken the manufacturing sector by storm. Almost every industry has adopted the recent advancements because they promise better future prospects and reduced costs. Same is the case with protective films manufacturing sector. This is how this sector is impacted by technological betterment:

- Quicker manufacturing is a result of shorter cycle times, which allows for an increase in production volume.

- More efficient processes that reduce power and material waste have contributed to cost reductions through advancements in manufacturing technology.

- Among other advancements, the product’s quality has also been enhanced by effective curing procedures, such as using ultraviolet radiation to firm adhesives, inks, and coatings.

- Additionally, improved curing technology has led to increased longevity of the products.

- Above all, the latest UV curing technology helps reduce negative impact on the environment by emitting low volatile organic compounds.

Overview of the UV Curing Technology

Rapid polymerization is the basis for UV curing. Liquids are transformed into solids through photochemical reactions caused by the material’s photoinitiators, which absorb ultraviolet light. Because the advantages of UV curing procedures outweigh those of conventional thermal curing, the former has replaced the latter. Let’s examine the factors that make UV curing the recommended option.

Increased Production Efficiency

As opposed to conventional curing techniques, which can take hours or even days, UV curing technology minimizes manufacturing cycles by allowing materials to cure in seconds or minutes. This rapid-curing technology helps manufacturers boost production capacity by reducing bottlenecks and generating more products in less time. UV curing devices effectively integrate into automated production processes, streamlining operations and decreasing downtime. The uniform curing of the technique increases throughput and uses resources efficiently, reducing errors and the need for rework.

Environmental and Cost Benefits

UV curing technology offers substantial economical and environmental advantages. By employing solvent-free or low-solvent formulations, UV curing dramatically reduces volatile organic compound (VOC) emissions in comparison to traditional methods, which often use solvent-based materials in protective film manufacturing. In addition to helping to satisfy stringent environmental standards, this encourages safer working conditions and cleaner air. Additionally, UV curing systems are energy-efficient and help to cut utility expenses because they operate at lower temperatures and use less electricity. The reduced requirement for solvents leads to lower material prices. Because of its extended lifespan and minimal maintenance needs, UV curing equipment is a cost-effective and environmentally responsible choice for enterprises.

Improvement in Product Quality

One cannot emphasize how much UV curing technology has improved the consistency and durability of protective film coatings. A flawless, smooth surface finish is guaranteed by the process, which improves the product’s look and functionality. High-quality outcomes are produced and contamination is less likely with rapid curing. An further well-known characteristic that contributes to the items’ increased longevity and durability is their remarkable resistance to chemicals, environmental factors, and scratches. For industries that need high-performance protective coatings, such automotive, electronics, and packaging, UV curing is the suggested choice.

Market Feedback and Demand Growth

The industry’s growing acceptance of UV curing technology is being driven by the overwhelmingly positive feedback that manufacturers and end users have given protective films created with this technology. The technology’s ability to produce films of exceptional quality that are astonishingly consistent and durable impresses manufacturers. Feedback highlights how shorter production cycles and consistent outputs made possible by UV curing increase overall operational efficiency and customer satisfaction.

Customers like UV-cured protective films’ improved qualities, which greatly increase the lifespan of coated products by preventing abrasions, damage caused by chemicals, and environmental influences. Additionally, because UV-cured films emit fewer volatile organic compounds (VOCs), they are environmentally benign, which is in line with customers’ growing desire for sustainable products.

Environmental Trends and Sustainable Development

Reliance on solvent-free or low-solvent processes helps reduce emissions of volatile organic compounds. In this way, UV curing technology aids in the accomplishment of sustainable and ecologically friendly industrial objectives. It is also more energy efficient than traditional methods because of its very low power consumption and lower temperature needs. This makes it perfect for sectors that need high-performance, eco-friendly solutions, such electronics and the automobile industry.

Marketing Strategy Recommendations

The following resources are suggested for promoting the usage of protective films created with UV curing methods:

- Produce instructional resources, including white papers, webinars, and explainer videos, to highlight the benefits of UV curing technology, including its efficacy, sustainability, and superior results. Pay attention to key industries including electronics, packaging, and autos.

- Present several case studies and manufacturer endorsements that demonstrate how UV curing technology has improved the sustainability and productivity of their operations.

- Participate in displays, conferences, and trade shows to highlight the potential of the technology through live product samples and demonstrations.

- Use social media, SEO-optimized content, and focused digital advertising to interact with potential clients. Highlight the advantages of UV curing for the environment to draw in companies that

- To support UV, team up with trade associations, academic institutions, and well-known thought leaders.

- Moreover, promotional campaigns for limited time, discounts and coupons, free samples, etc can also help people get a taste of films made with UV curing techniques and can convince them to adopt these films in the longer run.

Conclusion

The utilization of UV curing processes has yielded significant advantages, including improved product quality, reduced energy consumption, and greater production. Because of its ability to significantly reduce production cycles, lower environmental impact, and increase coating durability, it has grown in popularity across a variety of industries, including automotive, electronics, and packaging.

Positive market responses from producers and consumers further increase its potential, since demand is driven by its outstanding performance and compatibility with international environmental standards. Implementing targeted marketing tactics and promoting industry cooperation can help further expand the usage of UV curing technology and pave the way for more productive and ecologically friendly manufacturing processes.