Table of Contents

- Key Points for Choosing Glass Surface Protection Films

- Key Points for Choosing Metal Surface Protection Films

- Key Points for Choosing Plastic Surface Protection Films

- Selecting Protection Films Based on Different Application Scenarios

- Conclusion

- References

Meta Description

Learn how to choose the right surface protection film for glass, metal, and plastic surfaces, considering factors like scratch resistance, adhesion, flexibility, and weather durability.

Main Body

Considering getting impeccable protection for your product? Let us help you with the highest-quality protective films made to elongate your product’s life, protect it against damage, and give it an aesthetic appearance.

No matter what industry you are in, every product can benefit from a protective covering. For example, in the automotive industry, glass protective films are excessively used. Similarly, protective adhesive sheets for floors and carpets can be used to protect them against dust, pollutants, and damage. If you deal in furniture, that too needs protection against wear. In short, from protective tablecloth sheets to those made for a car’s windows every product needs protection whether it is in the manufacturing phase, in transit or being used by the end users.

Making the right choice while selecting a protective film for your product can significantly increase it life span and add to its aesthetics while keeping it clean and damage-free. This comprehensive guide will help you make a learned decision while selecting the right type of protective film.

Key Points for Choosing Glass Surface Protection Films

While selecting a protective film for glass surfaces, you need to keep in mind a few key factors. For example, it should provide resistance against scratches. Moreover, you need to choose a film that satisfies your transparency requirements. Let’s have a look at the key factors to consider for glass protective films;

- Scratch Resistance

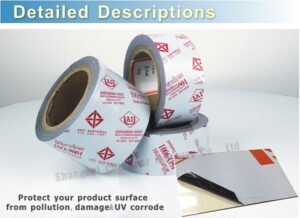

One of the basic traits of a glass surface protection film that you should look for is scratch resistance. Whether the glass surface is that of touch screen devices, building facades, or windows of automobiles, they are always prone to scratches during handling, transportation, and daily use. However, even minor scratches on their surface can significantly tarnish their appearance.

While selecting a glass protection film, for example an automobile protective film, make sure you go for an anti-scratch protective film. It should also have a desirable thickness to make sure it can absorb the damage without transferring its impact to the glass surface.

Our glass surface protection films are made keeping in view the specific requirements according to their intended use. We make sure, they provide resistance against scratches without impacting the aesthetic appeal of the surface. These films are meant to increase longevity of the glass which in turn reduces maintenance cost.

- Transparency Requirements

While narrowing down your search for a perfect glass surface protection film, keep in mind your visibility requirements. For example, for car windows, some prefer transparent film as the requirement is only scratch resistance. Others may prefer tinted films as they need some privacy as well. Similarly, our colored films also protect against UV light while still maintaining a clear view.

Key Points for Choosing Metal Surface Protection Films

Here are some of the most desirable traits you should prioritize while selecting a protective film for metal surfaces:

- Corrosion Resistance

Metal surfaces are highly susceptible to corrosion, especially when they frequently come in contact with moisture and chemicals. Whether you are looking for protection in the manufacturing phase, you are going to store the metal product for some time, transporting it to the end users, or simply putting them in use, go for a protective film that can provide resistance against corrosion in the long run while maintaining the product’s aesthetic appeal.

- Adhesion and Strength

An adhesive protective film that keeps itself firmly attached to the surface even under difficult conditions like extreme temperature changes, and rough handling during transportation will ensure utmost protection for the product. Moreover, it should be strong enough to resist peeling and should not come off easily under rough conditions. However, we also make sure that our metal surface protection film does not leave any residue after it is removed from the metal surface.

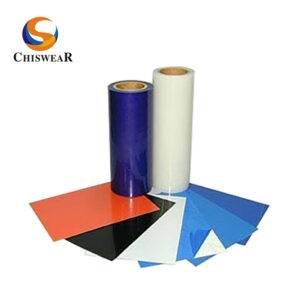

Key Points for Choosing Plastic Surface Protection Films

- Flexibility

Since the plastics are comparatively flexible and also have complex geometries with intricate details, make sure, the protective film you choose is flexible enough to conform to the complex details of the substrate. It should not peel or deform under stress and must not result in the lifting or wrinkling of the plastic during transportation and use.

- Weather Resistance

Plastics are sensitive to environmental factors like UV rays, stress, and temperature changes. A protective film that is weather-resistant can help against these damaging factors while elongating the lifespan of the product and enhancing durability.

Selecting Protection Films Based on Different Application Scenarios

While the difference in the nature of the product to be protected has a huge impact on which protective film you should choose, the conditions under which the products are used are also decisive in this respect. Let us have a look at how your choice should vary in line with different scenarios.

- Indoor Vs. Outdoor Differences

Since the products intended for indoor use are comparatively safer from harsh environmental factors, their protective films can be relatively thinner. The main aim here should be to resist scratches. Moreover, for products like interior furniture and appliances, the stress needs to be put on the aesthetic appeal while selecting a protective film. Here, you can also choose to save money and go for the films that do not offer UV resistance.

However, for outdoor use, the products need to be protected against environmental factors like temperature, moisture, damage caused by UV rays, and pollutants. Hence, stronger and thicker films are better suited for outdoor products to enhance durability.

- Long Term vs. Short Term Protection Needs

When a protective film is needed for short-term use, e.g. during transportation, or for temporarily storing the product, you can afford to save a bit by going for thinner films. Moreover, you need not invest in films with high adhesion.

However, when these are intended to provide long-term protection, traits like strength, adhesion, and protection against continued exposure to harsh environments should be taken into consideration. In such cases, the features like corrosion resistance, weather resistance, and UV protection will come into play.

Conclusion

Making a learned decision while choosing the protective film for your product is imperative to providing the utmost protection. It helps safeguard the product against damage both in the long run and short duration. While selecting a protective tape, you must give due importance to factors like corrosion resistance, flexibility, viscosity, the nature of use, etc. Making a well-thought-out decision not only provides superior protection for the product and enhances its longevity but also helps ensure a better user experience for the end users.

References

- https://chidecor.com/product-category/glass-protective-film

- https://en.wikipedia.org/wiki/Ultraviolet

- https://chidecor.com/product/stainless-steel-sheets-protective-film/

- https://www.stahl.com/beyond-chemistry-from-a-to-z/what-is-a-substrate#:~:text=For%20the%20coatings%20industry%2C%20a,rubber%2C%20paper%2C%20or%20leather.