Table of Contents

Meta description

Learn how to choose the best stretch wrap film for your needs based on temperature, humidity, UV exposure, and load requirements to ensure optimal product protection during transport.

Body

Stretch wrap films, also known by the name of pallet wrap films are used extensively during transportation. These are usually made with Lenier Low-Density Polyethylene (LLDPE). Stretch wrap films are wrapped around the goods during transportation to keep them tightly stuck together and to sit firmly on the palette so as to protect them against damage.

Although stretch films are very handy when it comes to ensuring the safety of the products, not all types of stretch films are effective under all circumstances. Their traits vary according to varying environmental conditions and hence their performance can be affected. This implies that you make an appropriate choice while selecting the type of stretch wrap film. The factors like temperature, moisture, exposure to chemicals, UV exposure, etc. can significantly impact how a specific type of stretch wrap film behaves under particular conditions.

Hence, here we are with a comprehensive guide on what factors you should keep in mind to make an informed decision about selecting a stretch wrap film.

Type Introduction

Depending on the specific properties and the manufacturing process used, stretch wrap films can be characterized in different types and each type is suitable for different applications under different conditions. Let’s have a brief overview of some of the popular types along with their properties and applications.

Cast Stretch Wrap Film

A cast stretch film is made by slowly and continuously pouring heated resin into a die. It comes out as a smooth film that is transparent in appearance and is not noisy when it is removed. This clear protective film can be used where the appearance matters and the product needs to be visible.

Blown Stretch Wrap Film

For manufacturing this film, hot resign is blown into bubbles and then made into roles. This film is translucent and is not appropriate to be used where complete visibility is required. However, it has comparatively higher strength and can be used for heavier loads. It makes a noise when it is taken off.

Pre Stretched Wrap

It has been stretched already to ensure ease of application. It is lightweight and can be used effectively to wrap high volume loads.

Hand Stretch Film

It is specifically designed for manual application. It is thin and flexible, making it easy to use. Hand stretch film is ideal for securely holding the load on the palette.

Colored Stretch Film

It is a type of hand stretch film that has color. During manufacturing, colors are added to this film. It is lightweight and easy to apply just like usual hand stretch film but is used specifically when color coding is needed to organize the goods during transport. Moreover, the added color helps protect the products against light.

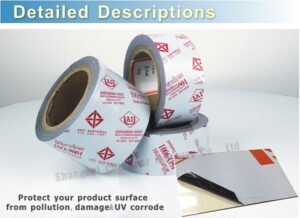

UV Stretch Film

It is made by adding UV blockers during the manufacturing process. The tape is particularly useful when the products are to be stored or shipped under the sun for some period of time and are sensitive to UV light.

Temperature Impact

The performance of stretch wrap films is considerably affected by temperature fluctuations. This is why, not every stretch wrap film is suitable to be used under all conditions. This is how their traits change with extreme temperatures:

- In colder conditions, or in cold storage, the stretch films may lose their elasticity. They become brittle and may not even cling. Hence, for colder conditions, tapes are made with certain additives that allow them to stay elastic and not lose their adhesive properties even when it is freezing.

- As the temperature gets higher, some types of stretch films may lose their structure. They become softer and some even melt at higher temperatures. In order to cope with hotter conditions, tapes with greater strength are used that can maintain their structural integrity under sunlight for extended periods.

Environmental Factors

environmental stimuli like moisture, humidity, sunlight, etc can have a significant impact on the traits of a stretch tape. So you need to make an informed decision, keeping in mind the conditions under which the tape will be used.

- In highly humid and moist conditions, a stretch tape may lose its strength and adhesive ability. Tapes may come off and not stick to the products properly. For such conditions, tapes with higher strength are used to withstand the moist conditions.

- When the tapes are used to store products in industrial setups, their performance can be affected due to exposure to the chemicals. They might get degraded due to continuous exposure.

- For the products that are stored under sunlight, in open storage facilities, continuous exposure to UV light can also compromise stretch film’s integrity or transfer the impact to the products.

Buying Guide

While buying appropriate stretch tapes for your products, make sure you make learned decisions based on the particular requirements. Where cost-effectiveness is one of the crucial factors to consider, temperature, moisture, UV exposure, etc should also be taken into account.

- While using the stretch tapes under humid and hot conditions, go for those varieties that have higher strength, e.g. blown stretch wrap film, so that they can maintain their integrity and adhesive capabilities.

- Similarly, if the tape will be used to protect the products placed under the sun, the varieties containing UV resistant materials should be preferred.

- While shipping more than one type of products, it is advisable to use colored tapes for the ease in sorting out the products.

- Keep in mind the amount of load that needs to be secured. For heavier loads, you should go with thicker types with greater durability. Whereas, when the products are lightweight and need to be secured to the palette, you can go for thinner, transparent protective wrapping fim that is easy to apply and ensure visibility.

Conclusion

In conclusion, selecting the right stretch wrap film is crucial to ensuring product safety and stability during transportation. Environmental factors such as temperature, moisture, UV exposure, and chemical contact significantly impact the performance of these films. By understanding the different types of stretch wrap films and how they respond to specific conditions, businesses can make informed decisions that optimize product protection, load stability, and cost efficiency. Prioritizing factors like strength, visibility, and environmental resistance ensures the chosen film meets the demands of various transportation and storage environments.

References

- https://www.shell.us/business-customers/shell-polymers/resources-and-insights/polyethylene-in-everyday-life-common-lldpe-plastic-products.html#:~:text=Linear%20Low%20Density%20Polyethylene%20(LLDPE,The%20United%20States%20Plastics%20Corp.

- https://chidecor.com/product-category/stretch-film

- https://en.wikipedia.org/wiki/Stretch_wrap

- https://chidecor.com/product/pe-packing-stretch-film/