Table of Contents

- Automation and Efficiency: How Surface Protective Films Enhance Production Efficiency

- Basic Functions of Surface Protective Films

- Application of Automation Technology

- Case Analysis of Enterprises

- Steps and Precaution

- Conclusion

- References

Meta description

Automated surface protection films enhance production efficiency by reducing damage, downtime, and costs, offering consistent protection for industries like Samsung and Tesla.

Body

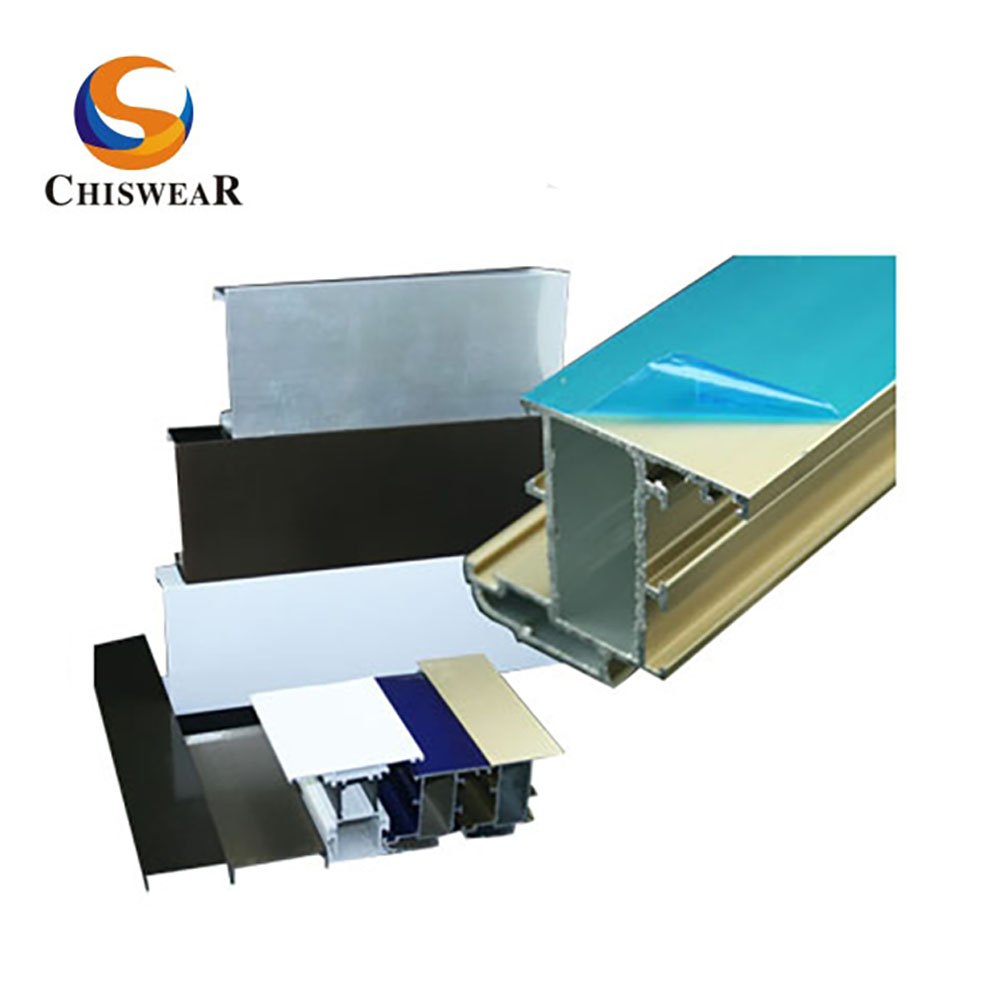

A Surface protection film has a huge role in safeguarding delicate surfaces against damage, especially during the manufacturing process, storage, and transportation. To maintain spick and span surfaces right from the moment they are manufactured, surface protection films are applied through an automated process. This helps protect them from scratches, rough handling during the manufacturing process and during storage, impact during transportation, and pollutants like dust.

The automated application of a surface protecting film during manufacturing makes the process seamless. The automated application also helps reduce downtime as the manufactured parts are readily applied with these films simultaneously. Moreover, the automation also omits the risk of human error, making the application as error-free as possible. It reduces the cost of labor as well, while helping to reduce maintenance costs in the longer run. Moreover, automation also ensures upholding the same, consistent application without mistakes. These are the benefits that have led to the adoption of automated applications of surface protection films.

Basic Functions of Surface Protective Films

Surface protection films have multiple roles to play. In addition to their basic function of protection, they also contribute to the overall look of the products. Let’s explore their multi-faceted roles in detail:

Damage Resistance

Whether it is a metal surface, plastic, glass, painted surface, or any other type of surface, protection films help safeguard them against damage including dents, scratches, scuffs, and breakage.

Moisture Resistance

where the manufactured product is sensitive to moisture, humidity and chemical exposure, surface protection films keep them from getting stained, corroded, and degraded due to these damaging agents.

Protection Against Pollutants

The environmental pollutants like dust and oil can compromise the quality of delicate surfaces. For example, electronic devices’ screens can easily get scratched due to these pollutants. Protective films act as a barrier against such pollutants.

Enhancing Visual Appeal

In addition to protection, surface protective films have a considerable role to play in enhancing the aesthetic appeal of the surfaces. They give them a sleek and presentable look. Moreover, by protecting them against damage, these films contribute to the overall appearance of the products.

Application of Automation Technology

Although protection films have an established role to play both in protection of the surfaces and their enhancement. However, the introduction of automation in their application has enhanced their protective abilities manifold, resulting in an improvement if overall production efficiency. Let’s have a look at how automation is helping in improving production efficiency:

· Reduction in Downtime

Automation makes the process of film application comparatively more speedy. It helps reduce the downtime that might be caused otherwise if the application was performed manually. This translates into increased output in the same time period, hence increasing production.

· Accuracy and Consistency

Machines and tools will always apply the films with the same precision. When you can expect consistent results every time, it helps remove any discrepancies and provides comprehensive coverage. This ensures better quality protection. Moreover, the occurrence of defects like bubbles, wrinkles, and uneven application is minimalized.

· Cost Reduction

Another huge benefit of the automated application of surface protection films is that it reduces the cost of labor required for application. Instead of the time-consuming and tedious task of applying a surface protection tape, workers can focus on more productive jobs and hence the efficiency of manual labor can be enhanced.

· Waste Reduction

Consistent application with zero error means that the material usage is optimized. It leads to minimal wastage and hence the cost of materials can be reduced significantly while also ensuring sustainable production.

Case Analysis of Enterprises

Industry giants have increased their production efficiency manifold and reduced the risks of damage to surfaces by automating the application of surface protection films. Let’s have a look at some real-life cases:

- Samsung has automated the application of surface protection films on the delicate screens of its electronic devices, and to the metallic parts. These films are applied to the devices during the manufacturing and packaging stages. By seamlessly integrating the surface film application with automated production, Samsung was able to enhance production efficiency.

The company reports at least a 20% to 30% increase in its production efficiency as a result of reduced damage to the surfaces in production and packaging lines. They had to spend less on rework which translated into reduced costs. Moreover, the automated application of surface protection films reduced the need for manual inspection of the items as consistent protection was provided every time.

- Tesla turned to automated surface protection film applications. This was especially useful in paint shops and in the assembly lines. The freshly painted surfaces were protected by a high-quality protective film to make sure they look new and are safeguarded against damage during assembly and shipment.

This resulted in 50% reduction in damage to the painted surfaces and the downtime was reduced by at least 15% due to automation both translating into increased production and reduced costs.

Steps and Precaution

1. Surface Type Assessment

Start by assessing and shortlisting the surfaces that need protection. For example, painted surfaces, glass, plastic, etc. Here, the type of risk should also be ascertained, e.g. scratches, dents, contamination etc.

Take precautions during assessment and make sure you have taken into account the type of coating and texture of the surface so that the right type of film might be selected.

2. Selection of Protection Film

Choose the right time of protection film keeping in mind the traits like required adhesive capability, thickness, and strength.

You need to be careful about selecting a film that might leave residue, or provide inadequate protection due to inappropriate thickness.

3. Selection of Automation Technology

You can either go for robotic application where highly precise mechanical arms with sensors apply the films, or you can rely on roll-to-roll application. The later is used for continuous surfaces like large metallic parts with lesser intricacies in design.

4. Synchronization with Production Automation

Make sure all the steps of application and removal of the films are well aligned with the existing automation. Moreover, to avoid damage, the application should be done write after the crucial production stages like painting and polishing. Similarly, the step of film removal should be done right before packaging.

Conclusion

In conclusion, the automated application of surface protection films has proven to be a game-changer for industries, enhancing production efficiency by reducing downtime, labor costs, and material waste. With consistent, error-free application, automation minimizes surface damage, ensures quality control, and optimizes productivity. Companies like Samsung and Tesla have demonstrated significant improvements in efficiency and cost savings by adopting this technology. As automation continues to evolve, its role in surface protection will only grow, offering even more benefits to manufacturers across various sectors.