Table of Contents

- Basic Characteristics of Static Film:

- Challenges Faced by Electronic Products:

- The Solution of Static Film

- Case Study

- Conclusion

- References

Meta Description

Discover how static protective films safeguard electronic devices from scratches, dust, and static buildup, ensuring durability and eco-friendliness with reusable solutions.

Main Body

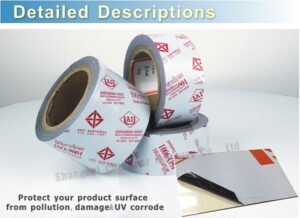

Electronic devices are always at risk of enduring damage right from the manufacturing stage to storage, transportation, and daily use. This is because they mostly have sensitive parts that are prone to scratches, damage due to dust and pollutants, and impact. In such conditions, the importance of a High quality protective film cannot be stressed enough. here, static films are mostly preferred due to their characteristics.

A static protective film helps safeguard fragile electronic products against damage caused by moisture, dust, grease, impact, rough use, and temperature fluctuations. Moreover, they help maintain the aesthetic appeal of the product. However, utmost care needs to be taken while selecting an appropriate protection film for electronic devices. Make sure you choose the perfect thickness and viscosity according to the intended use. Let us have a look at why these protective films are necessary for electronic products and what characteristics should they possess.

Basic Characteristics of Static Film:

There are several reasons why static films are preferred over other types of protective films when it comes to protective electronic devices. Let us have an overview of their basic distinguishing characteristics:

· No Need for Adhesive

As the name implies, these films make use of electrostatic charge instead of adhesives. this means, the film clings naturally to a surface.

· Seamless Application

Electrostatic charge makes it possible for these static films to adhere seamlessly to surfaces like the screens of smartphones and tabs. There are fewer chances of air bubbles and uneven application. Moreover, no tools are needed for the application.

· Better Visibility

These films are ideal for devices where transparency is needed. For example, they can be applied on the screens as these films are clear and do not obstruct visibility.

· Clean Removal

Forget about residue of the surfaces when the film is peeled off. Since these films only use electrostatic charge, there is no issue of residue on the screens when the film is removed.

· Reusable

Static protective films can be reused easily. This helps reduce waste as you can use these films many times.

Challenges Faced by Electronic Products:

Electronic products, as compared to other products are usually more prone to damage due to their sensitive nature. Here is why these products cannot do without a protective film:

· Prone to Scratches

Electronic devices are highly sensitive to damage caused by scratches and abrasions. even minor scratches can lead to significantly reduced customer satisfaction due to an impact on the aesthetic appeal of products like tablets, phones, and laptops.

· Smudge and Impact

The screens of electronic devices aren’t made to endure smudges and impact. Even the fingerprints can highly affect the visibility and appearance. These screens need to be protected right from manufacturing to storage, transportation, to daily use.

· Pollutants and Moisture

Dust particles, moisture, and grease can significantly impact the appearance and performance of electronic devices. It can damage their ports, screens, and circuits. Devices used outdoors like smartwatches are even more prone to such pollutants.

The Solution of Static Film

Keeping in view the highly sensitive nature of electronic devices, static surface protection films are highly capable of resisting damage while maintaining the pristine appearance of these devices. Let’s have a look at how these films can help protect sensitive surfaces.

· Scratch Resistance

Static protection films help ensure the safety of delicate surfaces in electronic devices, protecting them against scratches, abrasions, and scuffs. Thus they help maintain the aesthetic appearance of these devices during manufacturing, transportation and use. This ensures that the resale value of devices is not reduced.

· Protection from Pollutants

They act as a barrier against dust, moisture, grease, and pollutants. Hence the pollutants don’t stand a chance of accumulating on the sensitive parts, especially during storage and transportation, or outdoor use.

· Protection against Electrostatic Charge

As electrostatic charge build-up is a common occurrence in electronic devices, static films are preferred because of their ability to resist this build-up. They have anti-static traits protecting sensitive parts against damage from static charge.

· Eco-Friendliness

One of the biggest advantages of using static films is that they are highly eco-friendly. These films can be reused repeatedly without any effect on their performance. This reusability ensures lesser wastage of resources. Moreover, static films also help save a lot on adhesives.

Case Study

One of the very prominent examples of how the industry giants are relying on static films for flawless protection is that of Samsung. They are using static protection films to protect the screens of their Galaxy Z foldable smartphones. These films are especially preferred due to their ability to prevent charge build-up that can damage sensitive parts. Besides they offer seamless application without bubbles and are easy to remove as they don’t leave a residue. It helps reduce the damage while at the same time, the need for frequent repairs and replacements can be avoided.

Conclusion

Electronic devices usually have higher requirements for protection, especially during manufacturing, storage, and transportation. This is because they have sensitive components that are prone to damage. Keeping in view their risk-prone nature, static films are ideal for providing seamless, utmost protection. These films help reduce the damage caused by scratches, smudges, moisture, impact, rough use, pollutants, electric charge build-up, and grease accumulation. Even the giants like Samsung are relying on static protective films for the best possible protection for their electronic devices.