Table of Contents

- Latest Innovations in the Stretch Film Technology

- Case studies of stretch film application in the packaging industry.

- How to Enhance Transportation Safety

- Conclusion

- References

Meta description

Explore the latest innovations in stretch film technology for packaging, featuring eco-friendly materials and optimized production processes that enhance transport safety.

Body

No matter what industry you are dealing in, you simply cannot do without protective stretch films. Stretch film technology has become a part and parcel of every industry because it is needed to secure goods during storage and transportation. This film helps keep the products safe by keeping them securely packed on the palettes and restricting their movement. Moreover, these films also act as a barrier against dust, moisture, and damage caused by extreme temperatures and UV light.

Due to their transparency, stretch films can be used in a variety of industries including food, electronics, consumer goods, pharmaceuticals, and more. The ever-evolving technology in stretch film manufacturing has enabled these films to adapt to varying needs. From very tensile to rigid and strong, these can be made in various types depending upon the intended use. Similarly, the technology also allows these films to be made in varying levels of transparency and in different colors and viscosities. As e-commerce keeps on increasing, the demand for stretch films also increases. Owing to their increasing demand, stretch films with varying capabilities are being continuously introduced in the market. Recent years have seen a surge in eco-friendly stretch films as well.

Latest Innovations in the Stretch Film Technology

The increasing demand for stretch film in virtually every industry has led to remarkable innovations in the technology. Stretch films today are made with an array of traits depending upon how and where they will be used. Let us have a look at what latest innovations have been observed to make these films adapt to varying needs.

Advancements in Material Science

- The utilization of ultra-thin nono-layer technology has resulted in improving the material strength manyfold. It adds to the ability of these films to secure heavier loads. Besides, without making these films too bulky, the nanolayers make them more resistant to puncture.

- Another recent development in the material science for stretch films includes the shift towards more eco-friendly options. For example, an increase in the use of biodegradable options like polylactic acid and recyclable LLDPE and LDPE has been observed. These have resulted in a reduction in nondegradable plastic waste.

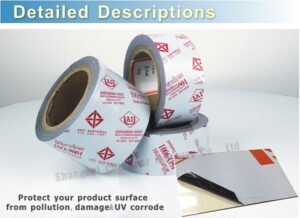

- Stretch film material has undergone a remarkable innovation in the form of the addition of performance enhancers. For example, the addition of UV stabilizers makes them more protective against UV rays. Similarly, some other additives are aimed at making the stretch films more efficient and last longer.

Optimization of Production Process

- One of the latest innovations in stretch film technology is the introduction of pre-stretch technology. It reduces the effort needed to stretch the film during application and also guarantees more efficient use of material, reducing waste.

- The production process today allows stretch films to be made more adaptive to specific needs. For example, you can tailor these films according to your needs when it comes to elasticity, thickness, color, and transparency.

Case studies of stretch film application in the packaging industry.

Let us have a look at some of the practical examples of stretch film applications across different industries.

Food Industry

Take the example of the meat industry. It extensively uses stretch films for packaging as it helps reduce leakage while at the same time, it prolongs the shelf life of meat by keeping it clean and acting as a barrier against air pockets. PVC is widely used in stretch films made for the food industry. It helps reduce spoilage and keeps the food fresh for long because it has good clinging ability and hence helps avoid air pockets. Moreover, high transparency makes sure the items are visible to the consumers. Moreover, these stretch films are in line with safety standards like FDA and hence ensure compliance.

Electronic Products

Stretch films are extensively used for securing delicate electronic devices like smartphones, TVs, laptops, etc. it helps secure them to the palette during transportation and also protects them against, scratches, impact, dust, and moisture. Moreover, these films are used for bundling electronic devices during transportation to keep them from moving and hence prevent damage.

How to Enhance Transportation Safety

Using the stretch tape right can help reduce the risk of damage to the goods during transport. No matter how high the quality of the tape is, if it is not applied with perfection, it will not deliver the desired results. Here is how you can ensure transport safety with stretch tapes:

- Wrap the palette and goods together to avoid excessive movement and reduce the risk of goods falling off the palette.

- Try layering the tape to make sure the goods remain intact during transport and there is minimal space for movement.

- When transporting goods with sharp edges or heavier load, go for the tapes with high resistance to breakage.

- Make sure, the cling of stretch tape is high enough to leave no room for the dust and moisture to enter.

- A zig-zag wrapping pattern with overlapping will create tight layers and hence reduce the chances of dust and pollutants damaging the goods.

Conclusion

Stretch film technology plays a crucial role in ensuring the safe packaging and transportation of goods across industries, including food and electronics. Recent advancements in material science, such as nanolayer films and eco-friendly materials, have significantly enhanced their strength, adaptability, and sustainability. Likewise, optimized production processes, like pre-stretch technology, contribute to reduced waste and better efficiency. Whether securing fragile electronic devices or preserving perishable food products, stretch films provide essential protection from movement, impact, dust, and moisture during transport. By using proper wrapping techniques, businesses can ensure that goods remain intact, secure, and protected throughout their journey.