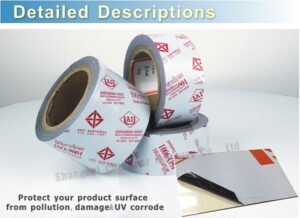

PE protective film, as a simple macromolecular organic compound, is the most widely used packaging material in the world today. PE protective film can be divided into: ultra-low viscosity protective film, low viscosity protective film, medium-low viscosity protective film, medium viscosity protective film, high viscosity protective film, ultra-high viscosity protective film according to viscosity.

1. Ultra-low viscosity PE protective film (micro-low viscosity)

Product features: thickness (0.03mm-0.15mm), width (1240mm, common specifications), peel strength (≤5g/cm), elongation (>400).

Product use: easy to use, easy to stick and tear, suitable for high optical surfaces, organic sheets, instruments, display screens, glass lenses, plastic lenses, etc.

2. Low viscosity protective film

Product features: thickness (0.03mm-0.15mm), width (1240mm, common specifications), peel strength (10-20g/cm), elongation (>400).

Product use: stable adhesion, good adhesion, easy to stick and tear, suitable for steel mirror plate, titanium metal, smooth plastic plate, silk screen nameplate, etc.

3. Medium and low viscosity PE protective film

Product features: thickness (0.03mm-0.15mm), width (1240mm, common specifications), peel strength (30-50g/cm), elongation (>400).

Product use: stable adhesion, good adhesion, excellent re-peeling function, no residual glue phenomenon, suitable for furniture Polaroid board, stainless steel plate, ceramic tile, marble, artificial stone, etc.

4 Medium viscosity PE protective film

Product features: thickness (0.03mm-0.15mm), width (1240mm, common specifications), peel strength (60-80g/cm), elongation (>400).

Product use: stable adhesion, good adhesion, easy to stick and tear, no residual glue phenomenon, suitable for fine-grained frosted boards and general difficult-to-stick materials surface protection, etc.

5. High-viscosity PE protective film

Product features: thickness (0.05mm-0.20mm), width (1240mm, common specifications), peel strength (80-100g/cm), elongation (>400).

Product use: stable adhesion, good adhesion, no residual glue phenomenon, suitable for fine-grained frosted boards, aluminum-plastic boards, difficult-to-stick plastic boards, etc.

6. Super high-viscosity PE protective film

Product features: thickness (0.05mm-0.20mm), width (1240mm, common specifications), peel strength (above 100g/cm), elongation (>400).

Product use: extremely high viscosity, easy to stick and tear, no residual glue phenomenon, suitable for rough-grained aluminum plates and other difficult-to-stick materials.